According to the EMC Directive, the presence of the CE marking becomes mandatory as soon as the equipment is placed on the market

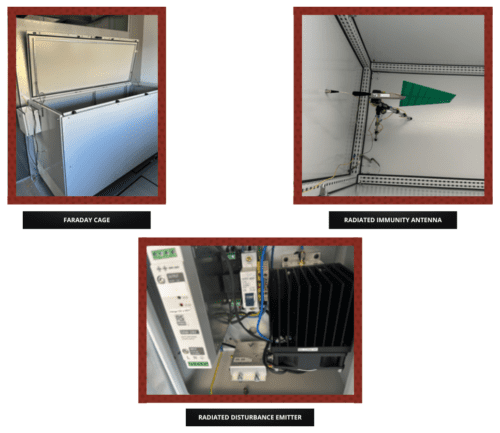

At SVE Corp. we perform two types of EMC tests in our laboratories: immunity tests and emission tests

CE certification, or CE marking, is a mandatory mark of conformity that certifies a product’s compliance with European Union safety, health and environmental standards. This mark, which stands for “Conformité Européenne”, is mandatory for certain product groups within the European Economic Area (EEA), including personal protective equipment, medical devices, machinery, electronics and toys.

It is also mandatory for all products manufactured in non-EU countries and placed on the market in the EEA. In this case, the importer must ensure that the non-EEA manufacturer has taken the necessary steps to obtain the CE marking.

The presence of the CE marking is a key indicator of a product’s compliance with EU regulations and facilitates free movement within the European market. By obtaining the CE marking, the manufacturer assumes sole responsibility for complying with the legal requirements to obtain CE certification, thereby ensuring that the product is suitable for sale in the European Economic Area.

This marking therefore has the following implications for manufacturers, importers and distributors:

- Manufacturers must carry out a conformity assessment, prepare a technical file and issue a CE declaration before affixing the mark to their product.

- Importers must verify that non-EU manufacturers have completed the necessary steps to affix the CE marking to the product.

- Distributors must provide documentation confirming that manufacturers and importers have completed the necessary steps to obtain the CE marking.

How does CE marking apply to electrical machinery?

In the field of electrical engineering, most equipment has the ability to generate or be susceptible to electromagnetic interference, regardless of its operating voltage level (or voltage range). It is important to note that CE marking under the EMC Directive has been mandatory since 1996.

In the European context, and in accordance with the Electromagnetic Compatibility Directive (EMC – 2014/30/EU), the presence of the CE marking becomes mandatory as soon as this equipment is placed on the market. This directive covers a wide range of equipment referred to as “apparatus” and fixed installations. However, there are specific exclusions, such as communication equipment, medical devices covered by the relevant directive, intrinsically safe equipment (e.g. simple cable harnesses) and radio equipment used by radio amateurs, among others.

It should be noted that the current directive (2014/30/EU) is not a safety directive. Other legislation covering the safety of radiation emitting equipment includes Regulation (EU) 2023/1230 and the Low Voltage Directive. Below is a short list of other relevant directives that apply to electrical equipment:

- CE marking Low Voltage Directive (Directive 2014/35/EU)

- CE marking Electromagnetic Compatibility Directive (Directive 2014/30/EU)

- CE marking Machinery Regulation (Regulation (EU) 2023/1230)

- CE marking of radio and telecommunications terminal equipment and mutual recognition of their conformity (Directive 1999/5/EC)

- CE marking Medical Devices Regulation (Regulation (EU) 2017/745 and Regulation (EU) 2017/746)

What are the requirements for EMC compliance?

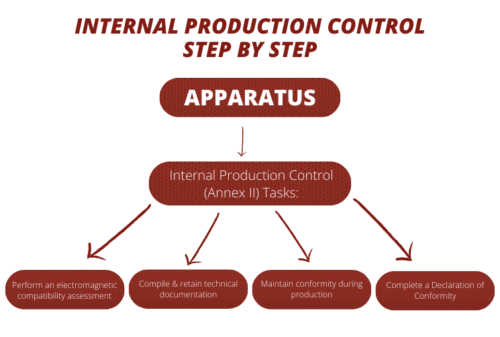

The main method of ensuring compliance of equipment with the Electromagnetic compatibility (EMC) Directive is known as “Internal Production Control”. This is a self-declaration process by manufacturers, but manufacturers can also choose to have their equipment assessed by a Notified Body (following the guidelines in Annex III of the Directive). The following is a summary of this process as set out in Annex II of the Directive:

The EMC Directive sets out two protection criteria that must be assessed when evaluating the electromagnetic compatibility of equipment:

- Ensure that the electromagnetic disturbance generated does not exceed the level at which other apparatus cannot operate normally.

- To ensure that the apparatus has a level of immunity to electromagnetic disturbance appropriate to its intended use, allowing it to operate without unacceptable degradation of its intended performance.

It is important to note that the Directive does not set specific emission limits or define immunity targets and therefore does not impose a testing obligation. However, not testing is often seen as a high-risk option. In contrast, comprehensive EMC testing to the applicable harmonised standards is generally considered to be the safer option.

Once the manufacturer has carried out these activities and verified that the equipment complies with all these requirements, it is considered ready to be CE marked and placed on the market.

SVE Corp. on the cutting edge of electromagnetic compatibility (EMC) testing

At SVE Corp’s in-house laboratories, we perform two types of EMC testing: immunity testing and emission testing. Immunity testing evaluates a device’s response to electromagnetic noise or other interference, while emission testing measures the amount of electromagnetic noise generated by a device during normal operation.

Under the current regulations, there are compliance criteria that indicate whether a product is compliant or not. They are classified as follows:

- Acceptance criterion A: Normal operation within the limits specified by the manufacturer.

- Acceptance criterion B: Temporary loss or temporary degradation of performance which ceases when the disturbance is removed; the equipment under test returns to normal operation without operator intervention.

- Acceptance criterion C: Temporary loss or temporary degradation of performance which requires operator intervention to correct.

- Acceptance criterion D: Loss of function or degradation of performance that cannot be recovered due to damage to equipment or software, or loss of data.

At SVE Corp. we have adopted Acceptance Criterion A as the standard for all of our products, providing additional robustness.

Our extensive testing, based on a thorough knowledge of EMC legislation, guidelines and regulations, focuses on the products developed by our R&D&I department. From design concept to final production, our products are modelled on the results of these tests.

Depending on the product, these tests may included:

- Radiated immunity via RF antenna.

- Radiated immunity in power and control cables.

- Coupling immunity in power and control cables.

- Immunity to conducted disturbances.

- Electrostatic discharge (ESD) immunity.

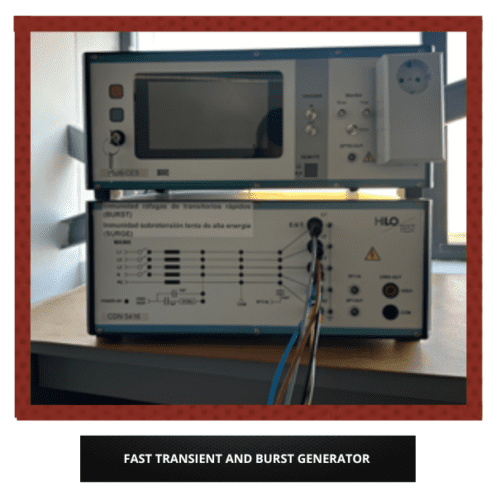

- Immunity to fast electrical transients and bursts.

- Immunity to voltage dips.

- Radiated emissions.

- Conducted emissions.

- Harmonic distortion.

- Voltage variations and flicker.

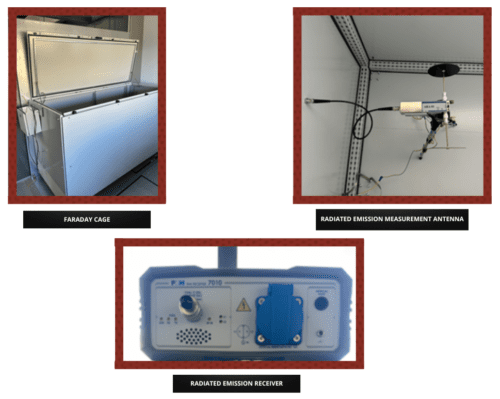

In order to carry out these tests, SVE Corp. has a complete laboratory that includes interference generating instruments and distortion measuring equipment, among which the following stand out:

1. Faraday cage for radiated emission testing of single-phase and three-phase equipment up to 400 Vac:

2. Faraday cage for radiated immunity testing of single and three-phase equipment up to 400 Vac:

3. Receiver and LISN to measure conducted and radiated emissions from single-phase and three-phase equipment up to 400 Vac:

4. ESD gun for electrostatic discharge testing up to 16 kVac:

5. Fast transient and burst generator for single-phase and three-phase equipment up to 400 Vac: